Hydal Components AB wishes a Merry Christmas & a Happy New Year!

Hydal Aluminium Profiler AB wishes everyone a Merry Christmas & a Happy New Year! We are closed from Friday 23/12-22 until Sunday 1/1-23. We open again Monday 2/1-23. Take care of each other during the holiday, and we look forward to a fantastic 2023!

Hydal Components AB wishes a happy summer!

Hydal wishes all our customers, suppliers and other partners a happy summer! We close for holiday week 28-31 and re-open Monday week 32. Take care of each other and remember to enjoy a well deserved vacation!

Petra bikes to Paris for Childhood Cancer Foundation!

Our CEO, Petra Olsson, will start on Saturday 9 July, cycling to Paris as a participant in Team Rynkeby – Good Morning. The team will arrive in Paris a week later, Saturday 16 July. The purpose of the project is to raise money for the Childhood Cancer Foundation. Since the start in 2011, the project has raised over 200 million for the Childhood Cancer Foundation. – Exercise has always been and is a big part of my life and something I continuously engage in. I have known about this project before and have been interested in signing up. This year it fit in with the rest of the life puzzle and I applied and came along, says Petra. The main purpose is to raise money for the Childhood Cancer Foundation and if you can then combine it with a real challenge, it is even better. We train together in my team almost every weekend and it is tough workouts, but it will be needed when you have to cycle 1200 km in one week. Hydal Aluminum Profiler AB also joins as Gold Sponsor to Team Rynkeby – Good Morning, Petra continues. We wish Petra good luck on the road! Team Rynkeby – Good Morning is part of a Nordic charity project that raises money for seriously ill children every year. The participants are organized in different teams that cycle together down to Paris. Since the start in 2011, the charity project has raised more than SEK 200 million for the Childhood Cancer Foundation. Today, the project consists of 2400 exercise cyclists and 550 officials divided into 57 local teams from Sweden, Denmark, Finland, Norway, the Faroe Islands, Iceland, Germany and Switzerland. Participants are selected from thousands of applicants who have filled in an application form on Team Rynkeby – Good Morning’s website. During the year, the participants will not only prepare to cycle just over 1,200 km to Paris, but also undertake to make an effort to raise money for children with cancer and their families. The participants spend several thousands of hours together collecting money and informing about childhood cancer.

Hydal Components AB wishes you a Happy Easter!

Hydal Aluminium Profiler wishes everyone a Happy Easter! Spring is said to be approaching, so take the opportunity to enjoy the sun this weekend

We welcome Marian and Sedin!

We welcome two new employees to Hydal Components AB, Marian Holmberg och Sedin Selimovic. Marian is a new Account Manager and has for the past seven years worked in the aluminum profile industry with products in the floor system segment. Sedin is the new Technical Manager and has extensive experience in the aluminum profile industry, especially in machining. We warmly welcome both Marian and Sedin to us!

Hydal Aluminum Profiler AB wishes Merry Christmas & Happy New Year !!

Hydal Components AB wishes everyone Merry Christmas & happy New Year! We are closed from Thursday 23/12-21 to Sunday 2/1-22. We open again Monday 3/1-22. Take care of each other during the holidays, and together we look forward to a fantastic 2022![vc_column width=”1/2″][vc_single_image image=”32872″ img_size=”large”]

Now we are in place at the fair!

Hydal Aluminum Profiler is now in place at its stand at Elmia Subcontractor and will be Tuesday-Friday this week. We are located in booth B08:35. You are very welcome to visit us. We look forward to meeting both existing customers and making new contacts for future business. From left Svein Inge Nerland, Jörgen Mähler and Petra Olsson.

Meet us at Elmia Subcontractor!

Now it is approaching Elmia Subcontractor in Jönköping and we are on site in booth B08: 35 from 9-12 November. We hope for many interesting visits to our stand by both existing and future customers. On site in our stand are staff from both the market and technology. If you are thinking of new articles in aluminum profile, feel free to come by and discuss this with us. Click here for free admission! [vc_column width=”1/2″][vc_single_image image=”32794″ img_size=”large”]

New saw machine in full swing!

Just before the holiday, a new saw machine for aluminum profiles was installed with us. A Pressta-Eisele Profilma 400V saw machine with feed magazine and dispenser with residual bit handling. Maximum profile width 200 mm, maximum profile height 125 mm. Now it is in full production and is very efficient. – The sawing machine is a new investment and means that we get increased capacity. Earlier this summer, we invested in a new DMG Mori, a horizontal multi-operation machine, and now we have taken another step to upgrade our machine park. Seeing the truck unload a new machine from the truck is the same feeling as on Christmas Eve! says Petra Olsson, CEO of Hydal Aluminum Profiler AB.[vc_column width=”1/2″][vc_single_image image=”32773″ img_size=”large”][vc_single_image image=”32771″ img_size=”large”][vc_single_image image=”32767″ img_size=”large”]

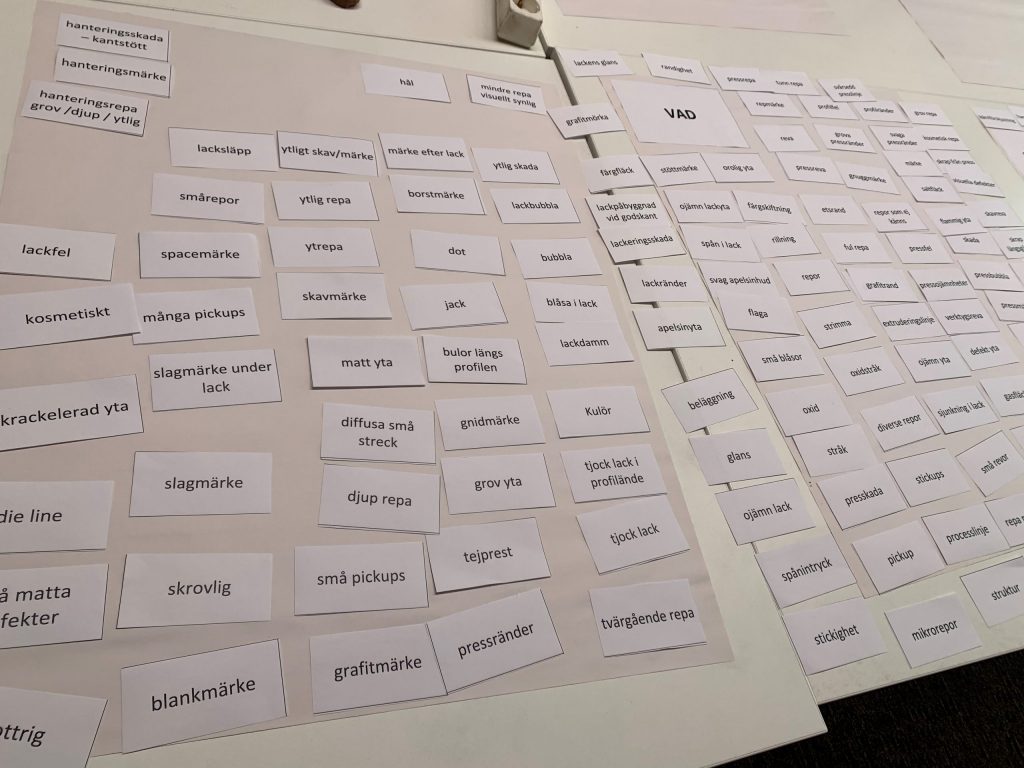

Hydal at workshop Metal Surf in Halmstad!

On Tuesday 14 September, Hydal participated in a workshop at Halmstad University. The workshop is part of the MetalSurf project. Group work was on the agenda and with a mix of customers, profile manufacturers, surface finishers and processing companies in the aluminum profile industry, there were very rewarding discussions that will hopefully contribute to a consensus on aluminum surfaces. MetalSurf is a project initiated by the industry organization Swedish Aluminum and funded by Vinnova in the program Metallic Materials. The project is led by Halmstad University and Jönköping University. The project is ongoing during 2020-2022 and the purpose and goal is to find a common objective way of assessing aluminum surfaces. This is, and has always been, a scourge for the industry in all years as the ambiguities in existing systems mean large costs for complaints and lead time losses. Therefore, this is an important project, especially for profile manufacturers, surface finishers, processing companies and, by extension, all end customers. [vc_column width=”1/2″][vc_single_image image=”32749″ img_size=”large”][vc_single_image image=”32750″ img_size=”large”][vc_single_image image=”32747″ img_size=”large”]